Metal Laser Cutting

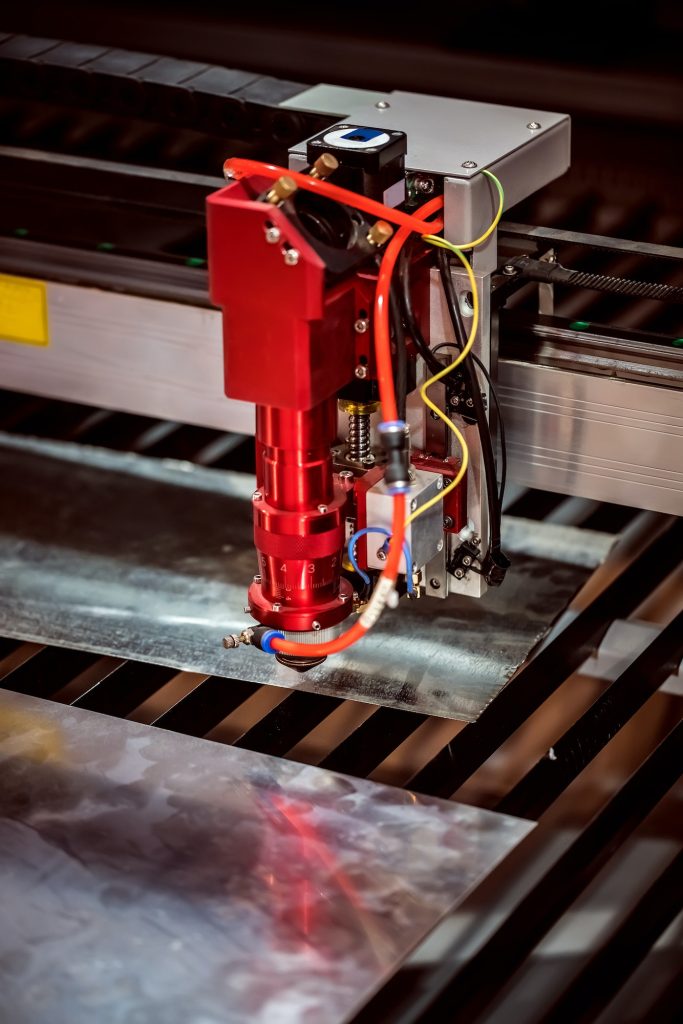

Metal Laser Cutting Service

Newton Engineering offers metal laser cutting in aluminum, steel, stainless, copper, brass, bronze, and nickel, with material thicknesses ranging from 0.02″ through 1.0″

Up to 1.0" Thick Material

Our 8 and 10 kW lasers can punch through steel, stainless, and aluminum up to 1″ thick, with remarkable cut quality and minimal burr.

In thick metals especially, cut quality depends significantly on heat buildup. Our machines help keep thick material cool by applying water cooling during the cut, and pierce splash-out is mitigated by spraying the material with a small amount of oil during the pierce.

Unrivaled Aluminum Quality

Aluminum is usually difficult to cut cleanly on a fiber laser. Anything above 1/8″ can usually be expected to have consistent burr along the entire cut edge. Thick aluminum plate cut on a fiber laser will have an edge burr up to 1/4″ in length.

We’ve used the latest cutting technology to almost completely eliminate cutting burr on aluminum up to 1″ thick. Even in 1″ aluminum plate, the amount of burr is lower than a fiber laser would ordinarily leave on 1/4″ plate.

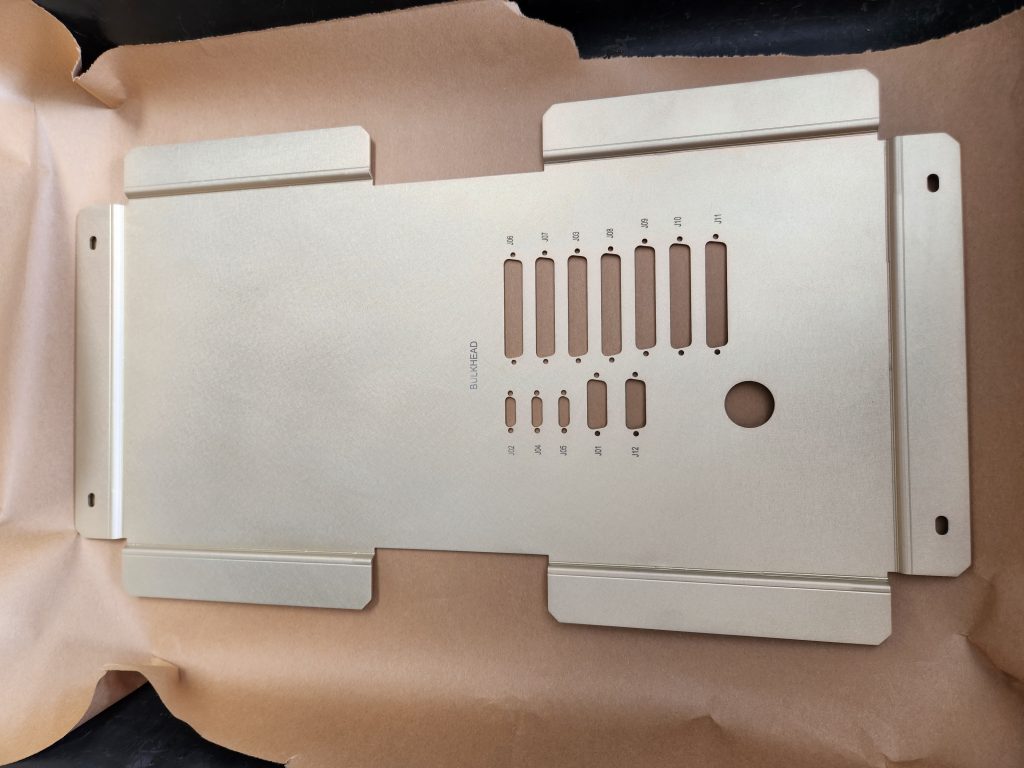

Precision Blank Cutting

Our fiber lasers produce blanks within +/- 0.005″ accuracy and ultra-high precision, with minimal to non-existent taper even in thick plate.

Order your parts knowing that you’ll receive consistent, precise performance on every part, every time.